Rivets are a necessary component of any aluminum boat. They are prone to becoming loose over time and eventually corroding, which can lead to leaks and holes in the boat. While replacing these rivets can be a hassle, it is definitely preferable to having a boat that is susceptible to water damage.

There are different types of rivets that can be used for aluminum boats, but close-end rivets are the best option as they make a water-tight seal. The usage of aluminum closed-end rivets is the best option to ensure that your boat is well-protected against water damage.

Since like metals do not react to one another, the use of aluminum rivets will not speed up the corrosion process of your boat. This is in contrast to using steel or brass rivets, which can actually cause more damage to the boat over time.

Aluminum rivets are also much easier to install than other types of rivets. This is because they do not require the use of a setter, which can save you a lot of time and effort.

Leaking aluminum boats are not only a nuisance, but it can also be dangerous. If you have a boat that is leaking, it is important to take care of the problem as soon as possible. Replacing corroded or loose rivets is one of the best ways to prevent further water damage and keep your boat in good condition.

These days all welded aluminum boats are preferred as they provide extra strength and don’t face the issue of rivets becoming loose over time. Less maintenance is required for welded aluminum boats and they last longer too.

Available in plenty of sizes, aluminum rivets are ideal for most applications. While they may not be the strongest type of rivet, they more than make up for it in terms of durability and resistance to corrosion. If you are looking for an affordable and effective way to repair your leaking aluminum boat, then closed-end aluminum rivets are the best option.

Why Closed-End Rivets on Aluminum Boats?

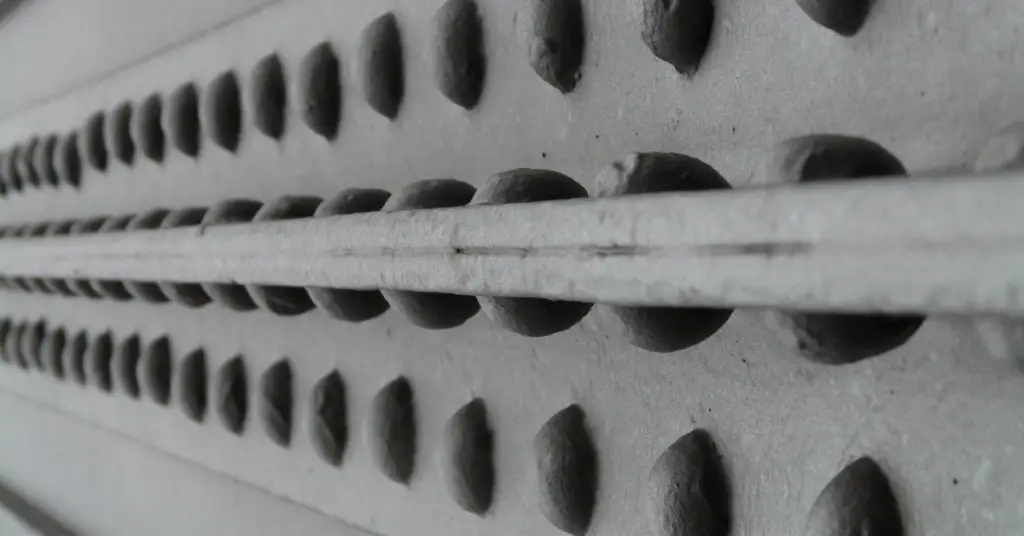

Closed-end blind rivets are tubular rivets with a closed end and a mandrel through the center. The entire rivet is inserted into a hole drilled in the parts to be joined, and the mandrel is pulled until it snaps off at a predetermined break point, expanding the blind end to securely lock the rivet in place.

Aluminum boats are often held together with closed-end rivets because they are less likely to corrode and weaken over time than other types of fasteners.

Unlike open-end rivets, which are inserted into a hole and then peened over to secure them in place, closed-end rivets are locked in place by the expanding blind end. This makes them much less likely to loosen or fall out over time, even in harsh marine environments.

Closed-end rivets are also less likely to cause leaks than other types of fasteners. The closed end prevents water from seeping into the hole and causing corrosion. This is especially important on aluminum boats, which are particularly susceptible to corrosion.

Being marine grade, closed-end rivets are also more resistant to vibration than other types of fasteners. This makes them ideal for use on boats, where vibrations from waves and the engine can cause other types of fasteners to loosen or fall out.

Other types of rivets that are quite often used include solid rivets and semi-tubular rivets. While these types of rivets have their own advantages, they are not as well suited for use on aluminum boats as closed-end rivets.

How to Install and Fix Boat Rivets?

Installing boat rivets is a simple process, but it requires the use of specialized tools. Rivet guns are available in both hand-held and pneumatic models. Pneumatic rivet guns are more powerful and easier to use, but they require an air compressor, which can be expensive and inconvenient to set up. Hand-held rivet guns are less powerful but more portable.

To install a boat rivet, first drill a hole through the parts to be joined. The hole should be slightly larger than the diameter of the mandrel. Next, insert the blind end of the rivet into the hole. Place the point of the rivet gun onto the head of the mandrel and squeeze the trigger. The gun will pull the mandrel through the rivet, causing the blind end to expand and lock the rivet in place.

If a boat rivet becomes loose or falls out, it can be fixed by simply re-installing it using the same process. If the hole is damaged, it can be repaired by drilling a new hole and installing a new rivet.

With drilling out of the way these joints are much stronger than conventional welding. Sealing the rivet heads on the exterior is also important to prevent corrosion. Many times a good sealer and paint job will make these joints nearly invisible.

Taking Care of Your Boat Rivets

Closed-end rivets are designed to be durable and resistant to corrosion, but they still require some care and maintenance to stay in good condition.

Rivets should be inspected regularly for signs of wear or damage. Any damaged or loose rivets should be replaced as soon as possible to prevent further water damage or instability.

To clean boat rivets, use a soft brush and soapy water. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish of the rivet. Once the rivets are clean, dry them thoroughly to prevent water spots from forming.

To check leaking rivets, apply a small amount of pressure to the rivet head with your thumb. If the rivet leaks, water will be forced out around the head. This is an indication that the rivet needs to be replaced.

Boat rivets are an essential part of any aluminum boat, and they should be given the care and attention they deserve. With proper maintenance, they will last for many years and provide a strong, reliable connection between the boat’s hull and deck.

The use of acid brush omission will help to remove corrosion from the rivets. If the rivets are extremely corroded, they may need to be replaced.

Are stainless steel rivets stronger than aluminum rivets?

Yes, they are but for your aluminum boats, we recommend using marine-grade aluminum rivets. As we know unlike metals react with each other to create an electrolytic reaction that causes corrosion. So, in order to protect your boat we recommend using marine-grade aluminum rivets.

It is always important to test a small area before starting a project to see if the materials are compatible. This step is quite often overlooked and can cause big problems down the road.

Conclude

Marine-grade closed-end rivets are an essential part of any aluminum boat. They provide a strong, reliable connection between the boat’s hull and deck and are resistant to corrosion. With proper care and maintenance, they will last for many years. If rivets become damaged or loose, they should be replaced as soon as possible to prevent further water damage or instability. To clean boat rivets, use a soft brush and soapy water. Avoid using harsh chemicals or abrasive cleaners, as these can damage the finish of the rivet. Once the rivets are clean, dry them thoroughly to prevent water spots from forming.

Clifford Slater is a seasoned writer with over 25 years of experience in boats and fishing trips. With his extensive knowledge and expertise in boats and fishing, he has become a recognized authority in the industry. Clifford has made it a point to regularly visit popular fishing destinations such as Florida and other places in the USA to stay up to date with the latest trends and techniques in the field.

Over the years, Clifford has acquired a wealth of knowledge about boats and fishing, which he has shared through his writing. His articles and books are widely read by fishing enthusiasts and professionals alike, and his insights are highly valued by those seeking to improve their skills in the field. Clifford’s passion for boats and fishing is evident in his writing, and his readers appreciate the depth of his expertise and his ability to communicate complex topics in an engaging and accessible way.

Clifford Slater’s impressive credentials and dedication to his craft make him a trusted authority in the world of boats and fishing. His commitment to staying up to date with the latest developments in the industry, combined with his deep knowledge and understanding of the subject matter, ensures that his writing is always informative and valuable. For those seeking to improve their skills or simply enjoy the beauty of the sea, Clifford’s writing is a must-read.